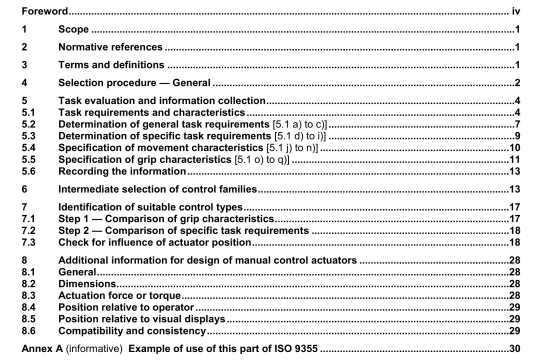

ISO 9355-3 pdf download – Ergonomic requirements for the designof displays and control actuators —Part 3: Control actuators.

The accuracy required in the operation of a manual control actuator Is determined by the task that has to be performed. Accuracy is Influenced by a number of factors, the most Important of which Is continuity of movement required, i.e. whether action of a manual control actuator takes place in discrete steps or continuously.

Adequate feedback of information to the operator is necessary to minimize mistakes in positioning.

High accuracy is inconsistent with high force application and the selection procedure takes this into account. thus, a requirement for high force and high accuracy together will not lead to the successful selection of a suitable manual control actuator.

Where control actuators are used frequently or for long durations, accuracy requirements are increased.

Accuracy in positioning relates to the accuracy of positioning a manual control actuator itself. Accuracy in the positioning of the controtlea component may be Increased by mechanical means. e.g. gears In this case, a high accuracy of positioning of the controlled component can be achieved by use of a manual control actuator capable of only low accuracy.

5.2.1.1 Discrete manual control actuator movements

A discrefe manual control actuator movement is erie where the manual control actuator can only be moved to

a number ol fixed positions e.g. rotary switch, on/off switch. The error in selecting the correct position

increases with the number of discrete positions. Thus, two positions shall be rated as “negligible”

requirements, while 24 positions shall be rated as “high’ requirements. Manual control actuators with more

than 24 discrete positions should be avoided.

Accuracy can be improved by, for example, feedback to the operator of information on the current value of the controlled variable, by clear labeling of manual control actuator positions. andlor by placing the manual control actuator where it can be easily seen and moved.

For manual control actuators, a visual indioation of the function of each position should be provided either by labels or a display.

Positions should not be indicated by numbers (“1w. “2’, etc) or letters (“A’, ‘B’. etc) to indicate a function.

since this requires the operator to remember the related functions and leads to mistakes, Labels 1,2… may be used where the value of the variable controlled varies from position to position at least on an ordinal scale. This becomes more m’iporlant as the number of discrete positions increases. Labels and displays shall be designed in accordance with ISO 9355-2.

When selecting control actuators whose functions are critical to avoiding Injury or damage to health, it is especially important that these requirements are followed,

5.2.1.2 ContInuous manual control actuator movements

Where movement of a manual control actuator corresponds to a continuous change in a controlled variable. the extent to which the variable deviates from the requwed value is a measure of error The probability of making an error depends mainly on the time allowed to complete the task (speed), availabdity of feedback of information to the operator, and operating force.

For continuous control actuator movements, appi’opnate feedback of information to the operator shall be provided, for example, by Indicating the direction and speed of the component controlled. This may be achieved by a display.by movements of other objects relative to the operator (e.g. movement of thesurroundings when driving a vehicle,movement of a lathe tool), or by other suitable means.

Where tasks have to be completed at speed, e.g.continuous tracking of a target, high accuracy can only beachieved by provision of low force demands as well as visual feedback of information.,For continuous trackingtasks, the requirements for accuracy in positioning the manual control actuator shall be rated as “very high”requirements.

The direction of movement of manual control actuators relative to the controlled component shall be inaccordance with ISO 447 for machine tools, IEC 60447 for electrical equipment, and IS0 9355-2.

5.2.2Task requirement b)—Classification of speed (speed)

The speed of operation required shall be assigned to a class in accordance with Table 1.

ISO 9355-3 pdf download – Ergonomic requirements for the designof displays and control actuators —Part 3: Control actuators