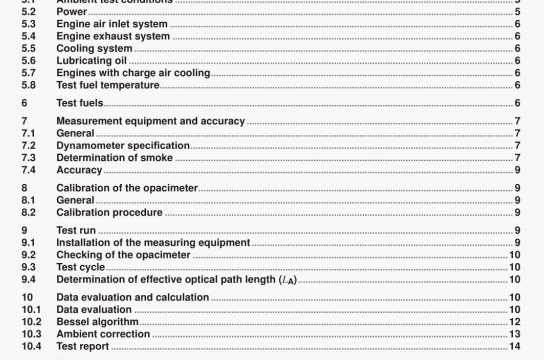

ISO 8178-9 pdf download – Reciprocating internal combustionengines— Exhaust emission measurement — Part 9: Test cycles and test procedures fortest bed measurement of exhaust gassmoke emissions from compression ignition engines operating under transient conditions.

10.1.3 Data conversion

Conversion froni as-measured smoke values to appropriate reporting units is a two-step process Since the basic measurement unit of all opacameters is transmittance, the first step In all cases Is to convert from transmittance (r ) to opacity at the as-measured effective optical path length (VA) using Formula (8). For most opacimeters this step is done internally and is invisible to the user.

The second step of the process is to convert from NA to the desired reporting units as follows

If the test results are reported in opacity units. Formula (9) must be used to convert from opacity at the as- measured effective optical path length (NA) to opacity at the standard effective optical path length (Nj.

NOTE In the event that the measured and standard effective optical path lengths are identical, NA5 is equal to 3A and this secondary conversion step s not required.

If the test results are reported in units of light absorption coefficient, then Formula (10) shalt be applied

10.1,4 Effective optical path length input values

In order to apply Formula (10), it is necessary to apply the as-measured effective oplical path length (LiJ. To use Formula (9). values shell be applied both for LA and for the standard effective optical path length Lp.

For full-flow end-of-line opacimeters. LA is a function of the engine tailpipe design For straight talçes with a circular cross section, LA is equal to the tailpipe inner diameter

For partial-flow (sampling) opacimeters and full-flow in-tine opacimeters. LA isa fixed function of the instrument measurement cell and purge air system design. Specification data supplied by the instrument manufacturer shall be used to determine the appropriate value for ‘A when these types of opacimefers are used.

typically, it i5 necessary to determine LA to within 0,002 m In order to achieve corrected smoke results that are accurate to within 2 % opacity.

Smoke opacity readings depend on the effective optical path length of the instrument. Since limit values may be established in units of percent opacity, they must be referred to the standard effective optical path lengths (pipe diameter) at whch the limit values apply. For meaningful smoke data comparisons, smoke opacity results

With the end-of-line opacimeter, the opacity of the full exhaust plume is measured as it exits the exhaust pipe.With this type of opacimeter, the effective optical path length is a function of the exhaust pipe design and thedistance between the end of the exhaust pipe and the opacimeter.

11.2.2 Components of full-flow opacimeter (see Figure 1)

11.2.2.1EP: exhaust pipe

With an in-line opacimeter, there shall be no change in the exhaust pipe diameter within 3 exhaust pipe diametersbefore and after the measuring zone. if the diameter of the measuring zone is greater than the diameter of theexhaust pipe, a pipe gradually convergent before the measuring zone is recommended.

With an end-of-line opacimeter, the terminal 0,6 m of the exhaust pipe shall be of circular cross section andbe free from elbows and bends. The end of the exhaust pipe shall be cut off squarely. The opacimeter shall bemounted centrally to the plume within 25 mm ± 5 mm of the end of the exhaust pipe.

11.2.2.2 OPL: optical path length

The length of the smoke-obscured optical path between the opacimeter light source and the receiver,correctedas necessary for non-uniformity due to density gradients and fringe effect. The optical path length shall besubmitted by the instrument manufacturer taking into account any measures against sooting (e.g. purge air).lf the optical path length is not available, it shall be determined in accordance with 11.6.5 of IS0 11614:1999.For the correct determination of the optical path length, a minimum exhaust gas velocity of 20 mls is required.

ISO 8178-9 pdf download – Reciprocating internal combustionengines— Exhaust emission measurement — Part 9: Test cycles and test procedures fortest bed measurement of exhaust gassmoke emissions from compression ignition engines operating under transient conditions