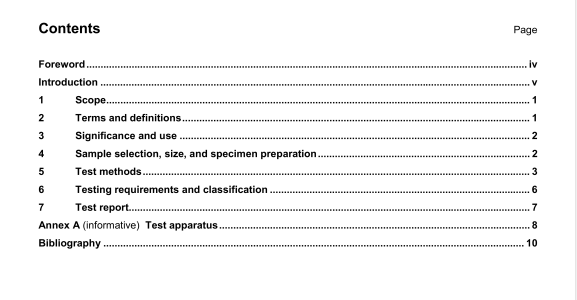

ISO 16936-4 pdf download – Glass in building -Forced-entry securityglazing – Part 4: Test and classification by pendulum impact under thermally and fire stressed conditions.

2.7

security-glazing composition

specific construction of a glazing product

NOTE A pro&xt is deemed to be of the serne or stçerior security-glazing composition ii tidividual plies are exchanged with others of a different colour, but without significant effect on the resistance to actions of force, andlor additional glazng products are Insted on either face of the security-glazing product. laminated to It or with an air space, and/or additional equipment such as alarm wires, heating wires, printing, or surface coatings (on part or all of the surface) are incorporated into the secasity-glazing product, provided that this does not signihcantty affect the resistance to actions of torce

2.8

security-glazing product

product based on glass with or without plastics with a single or multiple ply construction, where the individual plies are of uniform thickness over the whole area of the product.

NOTE A secawity-glazing product is usually transparent or translucent, and provides a specific resistance to the actions of force.

test pl.ce

specified piece of secunty-glazing product submitted to a specified test procedure

3 Significance and use

IMPORTANT — Security-glazing products should be installed In a frame which can give appropriate resistance to impact and which also provides a suitable support for the security-glazing product Cut-outs and holes In security-glazing products should be avoided where possible, as these can affect the resIstance of the product.

The test methods given In this part of ISO 16936 aid In assigning a level of physical security to glazing used In window and door assemblies based upon objective tests which can be consistently duplicated,

These test methods evaluate the resistance of secunty glazing to attacks using blunt and sharp impact devices and fire The test methods evaluate the performance of glazing in hot and cold environments, but do not provide a measure of the resistance or performance of glazing subjected to attack by ballistics, chemical agents, explosives or other extreme methods of attack. Where such elements are a factor, consult the manufacturer,

4 Sample selection, size, and specimen preparation

4.1 The s.amp.e submitted for testing shall consist of three test pieces one for each test,

NOTE To ensure against invalid test resiits because of errors dunng the test, it E advisable to submit at least one extra test piece.

42 Each test piece shall be (1 100 ± 5) mm long x (900 ±5) mm wide. The edges shall be free from visible chips, cracks and flaws. Glass samples should be lightly arrissed for ease of handling.

4.3 Figure A.1 shows an acceptable test fixture sketch and the location of the stnke points specified In Tables 1 and 2.

4.4 For non-symmetrical materials, the attack face of the product shall be identified by the manufacturer and attacked during the test process

This test is designed to evaluate the capability of security glazing to resfst repeated impact forces from both a blunt and a sharp Impactor under cold temperature conditions. Thes test is intended to closely simulate a sustained battering ram style or pounding type attack and provide an evaluation at the capability of the glazing to prevent, delay, or frustrate penetration and access to unauthoflzed areas under cold temperature conditions. An ripact test of this design performed on security glazing evaluates the impact strength of the glazing and its components as well as the quality of fabrication techniques.

5.1.2 Test apparatus

5.1.2.1 Large blunt impactor, consisting of a hinged or pivoted system with a mass of 36.3 kg capable of delivering impacts of 270 J to a glazing specimen mounted In a frame assembly, with a striking surface made from C1010.C1020 carbon steel and havrng a striking surface of 100±2 mm2 with rounded edges swnilar to a 4.5 kg sledgehammer head. See Figure A.4.

5.1.2.2 Sharp impactor, consisting of a hinged or pivoted system with a mass of 36,3 kg capable of delivering impacts of 135 J to a glazing specimen mounted in a frame assembly, with a striking surface made from C1010-C1020 carbon steel and the sharpness of the impactiig point similar to the end of a new firemans axe at the beginning of a test sequence. See Figure A.3.

5.1.2.3 Test fram., see Figure Al. Test frames of alternative designs may be used provided the same test parameters are evaluated,

5.1.3 Test procedure

5.1.3.1 CondItioning

Condition the panel at -25 ‘Cl 3 ‘C for a period of not less than 4 h. The protected surface temperature shall

be maintained -25 °C t 3 C during the test until an opening is created.

5.1.3.2 Installation

Install the panel into the test fixture with a minimum 30± 5 mm edge engagement Appropriate gasket rnatenal shall be used to keep glazing material from contacting the frame. Refer to the manufacturers recommendations.

ISO 16936-4 pdf download – Glass in building -Forced-entry securityglazing – Part 4: Test and classification by pendulum impact under thermally and fire stressed conditions