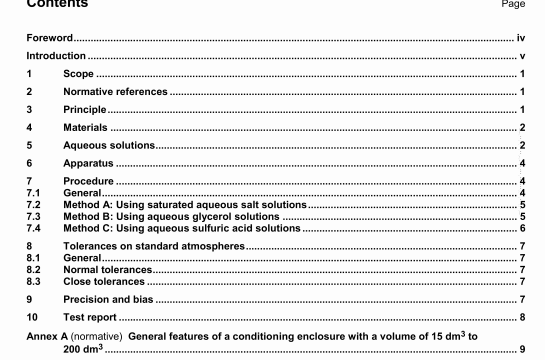

ISO 483 pdf download – Plastics -Small enclosures for conditioning and testing using aqueoussolutions to maintain the humidity ata constant value.\

For specimens with a small value of ITS (e.g. films), the total surface area may be up to three res the surface area of the solution.

In enclosures with air circulation, the total surface area of the specimens may be three times the area recommended for enclosures without air circulation.

It Is necessary to maintain the cleanliness of the surface of the solution and of the Interior waits of the enclosure Clean all interior surfaces of the chamber prior to each use. If the conditioning period Is more than one week long, dean the interior surfaces and replace the salt solution at least weekly. Duflng the cleaning process, the specimens shall be wrapped in a polyethylene film of at least 0.5 mm thickness and maintained at the conditioning temperature. If cleaning takes longer than 3 h, the test is invalidated.

7.12 Start of conditioning period

The duration of conditioning indicated in specifications for the specimens is counted, or testing in a specified atmosphere Is started, from the time, after introduction of the specimens, at which the enclosure has regained Its equilibnum state within the allowable tolerances, as indicated by the readings of the thermometers and hygrometer.

For each material conditioned/tested, determine the time necessary to reach the equilibrium state by placing the specimens in the enclosure set at the desired temperature and humidity and periodically removing and weighing the specimens until their mass is constant (to w,thm ± 0.5 %) for three successive weighings.

7.2 Method A: Using saturated aqueous salt solutions

Because the atmosphere above a saturated solution is easy to reproduce. this method is preferred whenever a salt can be found whose saturated aqueous solution produces the desired relative humidity at the given temperature (see Clause 3 and Table 1).

Unless otherwise specified, place the saturated aqueous salt solution In the chamber 24 h prior to placing the specimens in the chamber If data are available to show that the temperature and relative humidity reach the required values in less than 24 h. a shorter time may be used.

An excess of solid salt shall be in contact with the solution throughout the entire duration of conditionmg or testing. When at rest, the undissolved salt shall always be covered by at least 1 mm of water.

7.3 Method B: Using aqueous glycerol solutions

This method requires more atlention than the preceding one because the concentration of the glyceroL/water mixture must be maintained practically constant Specimens that absorb a large amount of water can cause significant changes In the concentration This may also occur If the load in the enclosise is too large in relation to the amount of solution used

The concentration & an aqueous glycerol solution, as indicated by its refractive index at 25 °C, is related to the relative humidity and temperature (see Table 2).

To produce the required relative humidity, the refractive index of the aqueous glycerol solution at 25 t at the wavelength of the sodium 0-line, n. is adjusted to the correct value, This is done by first calculating the refractive index at the wavelength of the sodium D4ine. 4, using the following equation:

9Precision and bias

The uncertainties in the relative humidities given in the literature for the methods described are theoreticalvalues.Temperature equilibrium between the air in the enclosure and the aqueous solution and pressureequllibrium between the water vapour in the air in the enclosure and the water vapour pressure of theaqueous solutions are taken for granted. These theoretical uncertainties are generally smaller than 2 % RH.They do not consider e.g. the influence of variations in the temperature of the air and the influence of testspecimens that absorb or release even small amounts of water.

The relative humidity in the enclosure is strongly influenced by any variation in air temperature.Even withoutany variation in the moisture content of the air, differences in the temperature of the air from one point in theenclosure to another will produce differences in the relative humidity.

ISO 483 pdf download – Plastics -Small enclosures for conditioning and testing using aqueoussolutions to maintain the humidity ata constant value