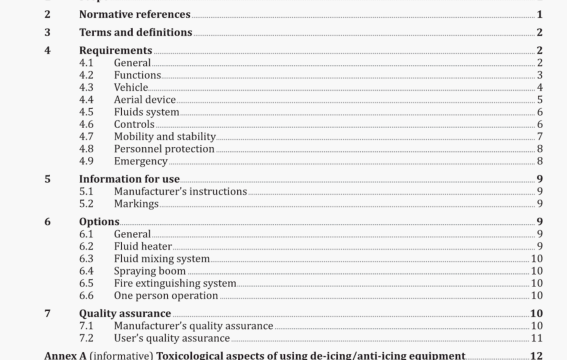

ISO 11077 pdf download – Aircraft ground equipment- De-icers Functional requirements.

4.2.4 A two-way vocal communication system shall be installed between the operator’s cabin or basket and the driver’s cabin, if separate. The operator’s cabin or basket headset, if applicable. shall be integrated or compatible with protective ear mufflers, and Its wiring’s routing shall be ergonomically designed In order to avoid any hazard or entanglement.

4.2.5 De-icers are intended to spray aircraft under freezing conditions with the following appropriate fluids mixed with water (if applicable) and heated as necessary in order to enable operators to de-ice/antiice aircraft In accordance with the detailed methods stated In ISO 11076:

a) ISO type I de-icing/anti-icing fluid (see ISO I 1075);

b) ISO type II. Ill, or IV de.lclngJantl-Iclng fluid (see ISO 11078),

4.2.6 De-icers can also be used, without spraying, as a means of technical staff access to elevated parts of aircraft, e.g. for maintenance. Reduced performance requirements can apply in such a case where identified in the present International Standard, but personnel safety requirements remain applicable.

4.3 Vehicle

4.3.1 The de-icer shall be based on a chassis rated and approved by the chassis manufacturer for the maximum intended loads and speeds of the de-icer. Alternately a custom built chassis is allowable under the manufacturer’s responsibIlity and shall substantiate loads and speeds ratings in an at least equivalent manner.

4.3.2 The dc-icer with operator’s cabin or basket in the stowed position should be capable of being driven at normal road speeds in accordance with applicable local airport regulations, or at least 32 km-h—1 (20 mph). When the operator’s cabin or basket is lifted from the stowed position, maximum speed shall be limited to no more than 1,7 m’st (6 km’ht, 4 mph) or, if lower, local safety regulations. Where this is ensured by interlocking, the corresponding safety device shall ensure a performance level “b in accordance with ISO 13849.1.

4.3.3 The drive train of the vehicle shall be designed for as smooth and jerk free driving as possible. It is further recommended to consider manoeuvring close to the aircraft. For this purpose, the possibility of driving with an inching/creeping speed should be considered.

4.3.4 An enclosed heated cabin for the driver, and optionally a passenger, shall be provided. The cabin shall be fitted with windshield wipers and a defroster/heater system. The design of the vehicle shall be such that no de.lclngJantl.iclng vapours can enter the chassis cabin (with windows closed) under any weather conditions. The cabin shall, as a minimum, be equipped with a mechanical filter on the air intake, for removal of aerosols produced. All seats shall be fitted with automotive type 3 points inertia reel safety belts.

4.3.5 The driver’s position shall have maximum unobstructed visibility, including of the operator’s cabin or basket under all operating conditions. This requires at least a large overhead transparent panel fitted with wipers and defrosting.

NOTE Where blind spots are unavoidable by design, e.g. at the rear of the vehicle, indirect means of vision such as mirrors or closed circuit television (CCTV) can be used to provide the driver with visibility in those areas.

4.3.6 Power steering as well as a power-assisted dual circuit service braking system and a parking brake shall be provided.

4.3.7 Mud/snow tires shall be provided on drive wheels. Drive wheels tire clearances shall be adequate for the Installation and operation of snow chains. Any vulnerable components shall be suitably protected against projections of snow or ice.

4.4 Aerial device

4.4.1 The de-icer shall provide an aerial device including a supporting boom, to which shall he attached either an enclosed operator’s cabin fitted with windshield wipers and a defroster/heater system, or (see Note in the Introduction) an open operator’s basket entirely surrounded by full guard-rails up to a height of at least 1.1 m (43 in) over its floor. Cabin or basket shall be rated for a minimum of two persons (minimum load capacity of 204 kg/450 lb), to provide for operators training and possible visual de-icing control by a separate qualified person, Where these obfrctlves are not retained, a cabin or basket Intended for a single person shall be rated for a minimum load capacity of 160 kg (350 Ib).

4.4.2 The operator’s cabin or basket and its supporting boom shall be designed to position an operator to effectively apply de-icingjanti-icing fluid to the upper areas of aircraft control surfaces, wings, vertical and horizontal stabilizers, and fuselage. Consideration shall be given to the height of these surfaces on aircraft types intended to b.c serviced while designing or selecting any de-icer type.

4.4.3 The operator’s cabin or basket shall have a self-adjusting mechanism to maintain a vertical operating attitude for all boom positions.

ISO 11077 pdf download – Aircraft ground equipment- De-icers Functional requirements