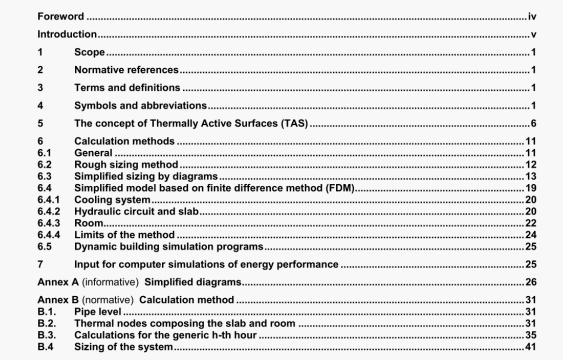

ISO 11855-4 pdf download – Building environment design-Design,dimensioning, installation and control ofembedded radiant heating and coolingsystems — Part 4: Dimensioning and calculation of thedynamic heating and cooling capacity of Thermo Active Building Systems (TABS).

— The hourly values 01 heat gains are calculated for the room under the design conditions and occupancy schedules, via an energy simulation tool or a proper method for the calculation of heat gains.

is the sum of the 24 values of heat gains

The heat gains calculation has to be carried out using an operative temperature O.5C lower than the average operative temperature during occupancy hours. for the sake of sale design. As a consequence, if the room operative temperature drift during occupancy hours is 21.0C to 26,0C, then the room average operative temperature during occupancy hours is 23,5C. and the reference room operative temperature for the calculation of heat gains is 23.0C.

6.3 Simphfled sizing by diagrams

In this case, the calculation of the heal gains has to be carried out by means of the value of the total cooing energy to be provided during the day in order to ensure comfort conditions at the average operative temperature (for instance, 23.0C), This method is based on the assumption that the entire thermally conductive part of the slab is maintained at an almost constant temperature duflng the whole day, due to its own thermal Inertia and the thermal resistance dividing It from the rooms over and below. This average temperature of the slab is calculated by the method itself and is used to calculate the water supply temperature depending on the running time of the circuil

The following magnitudes are involved in this method:

— ED: specific daily energy gains in the room dunng the design day: it consists of the sum of heat gains values acting during the whole design day, divided by the floor area fkWhIm2I.

— maximum operative room temperature allowed for comfort conditions rd.

Orientation of the room: used to detemNne when the peak load in heat gains happens: east (morning). south (noon) or west (afternoon).

— Number of active surfaces: distinguishes whether the slab works transferring heat both through the floor side and through the ceiling side or just through the ceding side (see Figure 9).

— : number of operation hours of the circuit Ihi.

— RIM: internal thermal resistance of the stab conductive region ((m2K!WJ It is the average thermal resistance that connects the conductive parts of the stab placed near the pipe level to the pipe level itself (see Figure 12).

— The hourly values 01 heat gains are calculated for the room under the design conditions and occupancy schedules, via an energy simulation tool or a proper method for the calculation of heat gains.

is the sum of the 24 values of heat gains

The heat gains calculation has to be carried out using an operative temperature O.5C lower than the average operative temperature during occupancy hours. for the sake of sale design. As a consequence, if the room operative temperature drift during occupancy hours is 21.0C to 26,0C, then the room average operative temperature during occupancy hours is 23,5C. and the reference room operative temperature for the calculation of heat gains is 23.0C.

6.3 Simphfled sizing by diagrams

In this case, the calculation of the heal gains has to be carried out by means of the value of the total cooing energy to be provided during the day in order to ensure comfort conditions at the average operative temperature (for instance, 23.0C), This method is based on the assumption that the entire thermally conductive part of the slab is maintained at an almost constant temperature duflng the whole day, due to its own thermal Inertia and the thermal resistance dividing It from the rooms over and below. This average temperature of the slab is calculated by the method itself and is used to calculate the water supply temperature depending on the running time of the circuil

The following magnitudes are involved in this method:

— ED: specific daily energy gains in the room dunng the design day: it consists of the sum of heat gains values acting during the whole design day, divided by the floor area fkWhIm2I.

— maximum operative room temperature allowed for comfort conditions rd.

Orientation of the room: used to detemNne when the peak load in heat gains happens: east (morning). south (noon) or west (afternoon).

— Number of active surfaces: distinguishes whether the slab works transferring heat both through the floor side and through the ceiling side or just through the ceding side (see Figure 9).

— : number of operation hours of the circuit Ihi.

— RIM: internal thermal resistance of the stab conductive region ((m2K!WJ It is the average thermal resistance that connects the conductive parts of the stab placed near the pipe level to the pipe level itself (see Figure 12).

ISO 11855-4 pdf download – Building environment design-Design,dimensioning, installation and control ofembedded radiant heating and coolingsystems — Part 4: Dimensioning and calculation of thedynamic heating and cooling capacity of Thermo Active Building Systems (TABS)