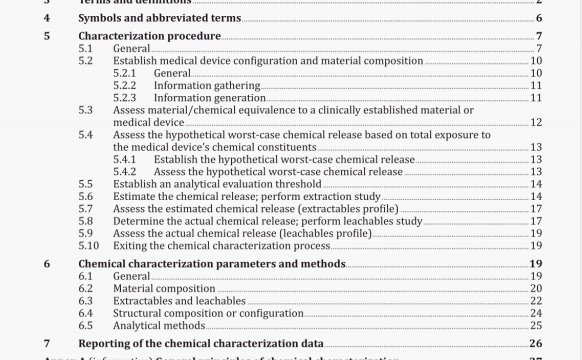

ISO 10993-18 pdf download – Biological evaluation of medicaldevices — Part 18: Chemical characterization of medicaldevice materials within a risk management process.

In some cases (e.g. change In the material supplier for a coniponentj, demonstration of material equivalence can be sufficient. Enough qualitative and quantitative information shall be obtained to determine whether a material under consideration is equivalent, in composition (including impurities), physical and chemical properties, processing and use, to a clinically established material. If a device or material is determined to be equivalent to a clinically established device or material, then that determination shall be justified and documented.

When an equivalent clinically established medical device can be identified and justified for the device under consideration, then the chemical characterization process shall be deemed to have been completed. When a clinically established equivalent medical device cannot be established and justified, then other elemenLs of a biological evaluation in accordance with ISO 10993-1 should be considered, including additional chemical characterization, as established by the additional steps in the flowchart system.

Material equivalence can be based on either material composition or extractable profile data compared to a clinically established material, provided that the analytical methods used to generate the data are ustlfied.

Physical, chemical, morphological and topographical characteristics (see ISO/TS 10993-19 and

ISOJTR 10993.22 as applicable) should be considered as appropriate when determining material

equivalence.

5.4 Assess the hypothetical worst case chemical release based on total exposure to the

medical device’s chemical constituents

5.4.1 Establish the hypothetical worst-case chemical release

The greatest potential chemical Impact of a medical device would be achieved lithe device’s entire composition were to transfer to the potentially affected individual during clinical use. this would be accomplished, for example, if an implantable medical device were to dissolve during clinical use or if an externally communicating device were to be completely leached during clinical use. Accordingly, the qualitative and quantitative data collected in &2 regarding the material or medical device configuration, materials of construction, process residuals and supplier information can be used to establish the hypothetical worst-case chemical release, even If It Is unlikely that this worst-case would happen under the clinical conditions of use. Additional factors shall be considered when establishing hypothetical worst-case chemical release, such as the medical device size and the possible clinical use of multiple devIces.

5.4.2 Assess the hypothetical worst-case chemical release

The health Impact of the medical device’s individual chemical constituents Is assessed by providing the hypothetical worst-ca’e chemical release, established In £4.1 to a risk assessor to establish the potential adverse impact that the chemical constituents could have on the health of a potentially affected Individual according to ISO 10993.1 and ISO 10993.17.

When exposure to a medical device’s entire composition can be established as being acceptable (e.g. by comparing the exposure to a safety threshold established in £). then the chemical characterization process shall be deemed to have been completed. The biological evaluation can then be completed according to ISO 10993-1. When exposure to a medical device’s entire composition is established to be potentially unacceptable, then the chemical characterization process can be continued by moving to the next step (see £5. £6 and Figure3). Alternatively. It can be appropriate to return to ISO 10993-1:2018 to continue forward with biological endpoint evaluation, if characterization information is not likely to provide further benefit.

NOTE I In some cases, theoretical compositional profiling might not be sufficient (e.g. If degradation products and unintended contaminants during manufacture are lIkely).

5.5 Establish an analytical evaluation threshold

An AET shall be determined and justified (see Annex). The AET should preferably be derived from a safety-based threshold (such as the TTC) but If this Is not practically achievable, an analytical threshold, such as the Limit of Quantification (LOQ) can be used as the reporting threshold. However, the difference between the AET and the LOQ shall be considered in the toxicological risk assessment and the difference shall be justified.

5.6 EstImate the chemical release; perform extraction study

An extraction study can be performed to Identify and quantify extractables for toxicological risk assessment per ISO 10993-17. In some cases (e.g. with exhaustive extractions), information on the release kinetics of extracted chemicals can be helpful. The extraction conditions used: exhaustive, exaggerated or simulated use shall be documented and justified. Annex D provides gtudance on principles of extractions.

ISO 10993-18 pdf download – Biological evaluation of medicaldevices — Part 18: Chemical characterization of medicaldevice materials within a risk management process