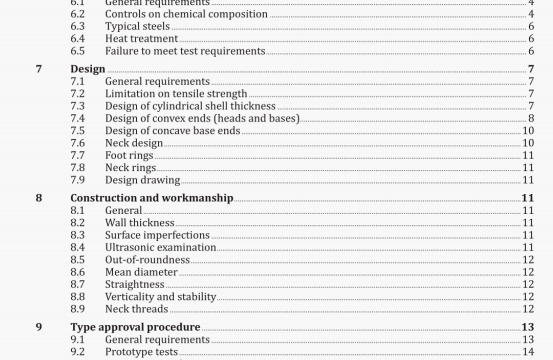

ISO 9809-1 pdf download – Gas cylinders -Design, constructionand testing of refillable seamless steelgas cylinders and tubes — Part 1: Quenched and tempered steel cylinders and tubes with tensile strength less than 1 100 MPa.

7.7 Foot rings

When a foot ring is provided, It shall be made of material compatible with that of the cylinder. The shape should preferably be cylindrical and shall give the cylinder stability. The foot ring shall be secured to the cylinder by a method other than welding, brazing or soldering. Any gaps which can form water traps shall be sealed by a method other than welding, brazing or soldering.

7.8 Neck rings

When a neck ring is provided, it shall be made of material compatible with that of the cylinder and shall be securely attached by a method other than welding, brazing or soldering.

The manufacturer shall ensure that the axial load to remove the neckring is greater than 10 times the weight of the empty cylinder, but not less than 1 000 N and that the torque to turn the neck ring is greater than 100 Nm.

7.9 Design drawing

A fully dimensioned drawing shall he prepared, which includes the specification of the material and details relevant to the design of the permanent fittings. Dimensions of non-safety related fittings can be agreed on between the customer and manufacturer and need not be showii on the design drawing.

8 ConstructIon and workmanship

8.1 General

The cylinder shall be produced óy

a) forging or drop forging from a solid ingot or billet, or

b) manufacturing from seamless tube, or

c) pressing from a flat plate.

Metal shall not be added in the process of closure of the end. MdnuidurIIIg dcicia MI.III uUL tie corrected by the plugging of bases (e.g. addition of metal by welding).

8.2 WaIl thickness

During production, each cylinder or semi-finished shell shall be examined for thickness. The wall thickness at any point shall be not less than the minimum thickness specified.

8.3 Surface imperfections

The internal and external surfaces of the finished cylinder shall be free from imperfections which could adversely affect the sale working of the cylinder. For examples of imperfections and assistance on their evaluation, see AnnxA.

8.4 Ultrasonic examination

8.4.1 After completion of the final heat treatment and after the final cylindrical wall thickness has been achieved, each cylinder shall be ultrasonically examined for internal, external and sub-surface imperfections in accordance with Annex..B.

8.4.2 In addition to the ultrasonic examination as specified in 8.4.1, the cylindrical area to be closed[which creates the shoulder and, in case of cylinders made from tube, also the base) shall be ultrasonicallyexamined prior to the forming process to detect any defects that after closure could be positioned in thecylinder ends.

In case of cylinders produced from tube (provided that the thickness of the tube is unaltered) thisadditional test is not required if the tube is 100 % ultrasonically tested before closure of the ends inaccordance with Annex B.

The test shall be performed as close as possible to the open end of the shell.

The untested area shall extend to a length of not more than 40 mm from the open end of the shell.ln both 8.4.1 and 8.4.2 it is not required to perform the ultrasonic examination for small cylinders witha cylindrical length of less than 200 mm or where the product of p × V<600 bar.1 (for Rma z 650 MPa)or px v< 1 200 bar. 1 (for Rma<650 MPa].

NOTE This examination does not necessarily cover the tests required in 6.4.2.

8.5Out-of-roundness

The out-of-roundness of the cylindrical shell, i.e.the difference between the maximum and minimumoutside diameters at the same cross-section, shall not exceed 2 % of the mean of these diameters.

8.6 Mean diameter

The mean external diameter of the cylindrical part outside the transition zones on a cross-section shallnot deviate by more than ±1 %% from the nominal design diameter.

8.7Straightness

The maximum deviation (b]) of the cylindrical part of the shell (,) from a straight line shall not exceed3 mm per metre length (see Figure 3).

8.8Verticality and stability

For a cylinder designed to stand on its base, the deviation from vertical (a) shall not exceed 10 mmper metre length (2)(see Figure 3) and the outer diameter of the surface in contact with the ground isrecommended to be greater than 75 % of the nominal outside diameter.

8.9 Neck threads

The internal neck threads shall conform to a recognized standard agreed between the parties to permitthe use of a corresponding valve thus minimizing neck stresses following the valve torqueing operation.Internal neck threads shall be checked using gauges corresponding to the agreed neck thread or by analternative method agreed on between the parties.

NOTE For example,where the neck thread is specified to be in accordance with ISO 11363-1, thecorresponding gauges are specified in IS0 11363-2.

Particular care shall be taken to ensure that neck threads are accurately cut, are of full form and freefrom any sharp profiles,e.g. burrs.

ISO 9809-1 pdf download – Gas cylinders -Design, constructionand testing of refillable seamless steelgas cylinders and tubes — Part 1: Quenched and tempered steel cylinders and tubes with tensile strength less than 1 100 MPa