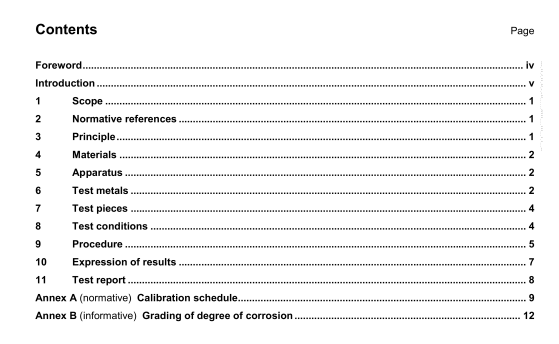

ISO 6505 pdf download – Rubber, vulcanized or thermoplastic—Determination of tendency to adhere to and corrode metals.

NOTE This test is convnonly carried out at low humidity to ensure that corrosion resulting from causes other than those due to the rubber is minimized.

9 Procedure

9.1 PrecautIon

In all operations, it is essential that the rubber test pieces and the metal test strips are handled only by means of the polyethylene gloves or other protective equipment (see 5.4). This precaution is essential in order to minimize surface contamination of the test piece and metal stnps.

9.2 Preparation of rubber test pieces for testing

Clean all the surfaces & the rubber test pieces with cotton wool pads moistened with a suitable solvent (see 4.2) to remove surface contamination (by mould release agents, for example). The solvent to be used will depend on the rubber under test, it shall not have any deletenous effects on the rubber (eq. acetone should not be used for nitrite rubber; isopropyl alcohol is preferred for this material).

Allow the test pieces to dry in at. When dry, store the test pieces, unless otherwise specifIed, in a clean desiccator over silica gel at standard laboratory temperature (see ISO 23529) for at least 24 h immediatety prior to testing.

Since cleaning of the test pieces may also remove from the rubber surface materials such as waxes, antlozonants, etc., which would normaly be expected to affect the adhesion and corrosion properues of the rubber, allow sufficient time in the desiccator for the re4ormation of the orlginar surface before testing.

9.3 Number of metal test strips

For each test, use two suitable metal test stops as specified In the material specification or selected from the metals specified in Clause 6.

For tests in a wet atmosphere, only like metals shoP be used in the construction of the test piece “sandwich in order to avoid electrolytic effects.

9.4 Preparation of surfaces of metal test strips

Thoroughly scour the test surfaces of the metal test strips using a slurry of pumice powder (4.3) in water applied with a cotton wool pad until a malt surface is obtained. Thoroughly rinse the metal strips with water (4.4) and then with acetone (4.1) and finally dry in air. If the prepared metal test strips are not to be used Immediately after cleaning, store them in a clean desiccator over silica gel for not more than 24 h before testing.

At the end of the test period, remove the sandwich from the test chamber, allow to cool. if appropriate, to standard laboratory temperature and maintain it at this temperature for at least 1 h. Release the screw clamps and carefully separate the metal stnps from the rubber test pieces. Examine the surface of the metal previously in contact with the rubber for signs of adhesion and corrosion Use a magnifying glass (5.5) in examinmg for corrosion.

9.5.1.2 Tests using 0-rings

Take two 0-rings of the same size, es specified in 7.1.2, prepared as speofied in 9.2, and two metal strips of dimensions 50 mm by 100 mm, prepared as specified in 9.4. Place the 0-rings between the prepared surfaces of the metal strips so that they are approximately 40 mm apart and approximately equidistant from the ends of the metal strs. Align the metal/rubber sandwich so formed lithe support jig and apply a load L in accordance wilti Table 3 to the test piece sandwich Tighten the two screw clamps, one at each end of the sandwich, with just sufficient force to maintain the damping force when the load is removed. Remove the load from the jig, place the sandwich in the test chamber (5.3) and maintain It at the test temperature for the test period (see Clause 8).

At the end of the test period, remove the sandwich from the test chamber, allow to cool, if appropriate, to standard laboratory temperature and maintain it at this temperature for at least 1 h. Release the screw clamps and carefully separate the metal strips from the rubber 0-rings. Examine the surface of the metal previously in contact with the rubber for signs ot adhesion and corrosion. Use a magnifying glass (5.5) I, examining for corrosion.

9.5.2 Tests In a wet atmosphere

9.5.2.1 Tests using sheet material (square test pieces)

Take two rubber test pieces as specified in 7.1.1. prepared as specified in 9.2. and two metal strips of dImensions 50 mm by 100 mm, prepared as specified in 9.4. Ptace the two pieces of rubber between the prepared surfaces of the metal strips so that they are approximately 40 mm apart and equidistant from the ends (see Figure 1). Align the rubber/metal sandwich so formed in the support jig and apply a (10 ± 0,1) kg weight (equivalent to 122,5 kPa acting on the rubber) to the test piece sandwich. Tighten the two screws, one at each end of the sandwich, with just sufficient force to maintain the clamping force when the 10kg weight is removed Remove the 10 kg wei’it from the jig, place the sandwich in the test chamber (5.3) and maintain it at the standard laboratory temperature and a relative humidity of (90 5) % for the test period (see 8.2).

ISO 6505 pdf download – Rubber, vulcanized or thermoplastic—Determination of tendency to adhere to and corrode metals