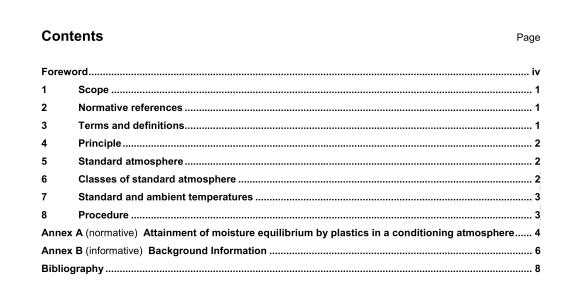

ISO 291 pdf download – Plastics -Standard atmospheres for conditioning and testing.

2 Normative references

The following referenced documents are indispensable for the application of this document, For dated references, only the edition cited applies For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 62, PlasIrc,s — Determination of water absorption

3 Terms and definitions

For the purposes of this document the following terms and definitions apply.

standard atmosphere

preferred constant atmosphere for which specific air temperature and humidity values, as well as limit ranges for atmospheric pressure and air-orculation velocity, are specified, the air not having any significant additional Constituents and the atmosphere not being subject to any significant additional radiation influences

NOTE 1 Standard atmospheres permit a defed state to be attained and maintained for samples or specimens. NOTE 2 Standard atmospheres correspond to the average atmospheric condibons in laboratories and can be estllshed In conditioning (controlled atmosphere) cabinets, dambers or rooms

3.2

condItioning atmosphere

constant atmosphere in which a sample or test specimen is kept before being subjected to a test

3.3

test atmosphere

constant atmosphere to which a sample or test specimen is exposed throughout a test

3.4

conditioning

one or more operations intended to bring a sample or test specimen into a state of equilibrium with regard to temperature and humidity

3.5

conditioning procedure

combination of the conditioning atmosphere and the period of conditioning

The amount of moisture absorbed by a test specimen conditioned in an atmosphere and the rate of mossture absorption or desorptcn vary significantly depending on the nature and the shape of the material of which the specimen Is made.

The conditioning times given in 8.1 may not be satisfactory, especially in the following cases:

— specimen materials and specimen thicknesses that are known to reach equillbnum with their conditioning atmosphere only after a long period of time (for example, certain polyamides and thicknesses over 2 mm, see ISO 62);

— unfamiliar materials, for which neither the capacity for absorbing moisture nor the time required to reach equilibrium can be estimated beforehand.

In these cases, use one of the following procedures:

a) Dry the material at an elevated temperature that will not significantly or permanently change the material (for many materials, a temperature of 50 C ±2 ‘C is acceptable) Allow the specimens at least 2 h to cool to the test temperature in a desiccator. State in the test report that the conditioning did not conform to ISO 291 but was a recommended altemative for special cases.

b) Condition the specimens In atmosphere 23/50 until equilibrium has, to all intents and purposes, been reached. A sufficient tame is the time t at whIch 70 % of the water content at saturation Is reached, as defined in ISO 62. If the time as defined in ISO 62 corresponds to a specimen of thickness 4 calculate the conditioning time t necessary for specimens of other thicknesses using Equation (Al).

ISO 291 pdf download – Plastics -Standard atmospheres for conditioning and testing