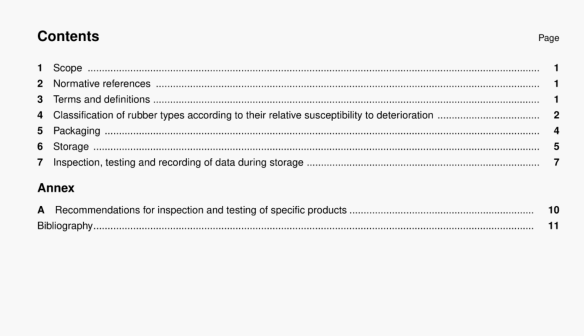

ISO 2230 pdf download – Rubber products -Guidelines for storage.

— if it is not possible to package the items ii either of these ways, suitably enclosed or wrapped so as to prevent free access of air.

NOTE I Under cerlain conditions sacore nAter (0) deteriorates I totally enclosed and m these cases free access of air Is advisie provided other detenorataig agencies (see 6.2) are avoided.

NOTE 2 It a advisable that paciag.ng be completed as soon as is reasonably pract.catzle alter curng in the case of a vulcanized rutter product, or as soon as reasonably practicable after manufacture in Pie case ol a thermoplastic rubber product.

The packaging should be carried out in an atmosphere in which the relative humidity is not 9reater than 65% (see 6.2.2) and under conditions that will ensure freedom from contamination by dust, oil, grease, etc.

If it is necessary for rtdter components to be packed in assembly sets, the components should be retained in their original identitying envelopes within the main package.

No part should be tied or tagged in such a way as to cause damage.

5.2 Packaging materials

All malarial 01 any containers, covering or wrapping snouid be free from substances, such as copper napnthenates or creosote preservatives, having a degrading effect on the rubber.

Heat-sealable opaque materials should be used unless it cart be demonstrated that this is not practicable in lhe circumstances or would distort the packaged pro&ict.

NOTE I Some suitable rnatenals are polyemylene-coated kraft per, Miininsan toiLpaper.polyethyiene laminate and opaque polyethylene 11km

Plasticized poly(vlnyl chloride) (PVC) film, or any other film containing plasticizer, should not be used in direct contact with the rubber If for any reason a transparent or translucent material is used. it should be over-wrapped with an opaque material.

If polyethylene is used as a single wrappng. it should be not less than 0,075mm thick (determined in accordance with ISO 4591).

NOTE 2 For some prockicts. anlistatic plastics wrapping ma be required

Where there is serious risk of ingress of moisture (see 6Z2). akiminium foitpaperipolyethylene laminate or other similar means of protection should be used to ensure protection from Ingress of moisture.

6.2.10 Contact between different products

Contact between products made from rubbers of different compositions should be avoided. This includes products

differing only in colour.

6.2.11 Products with rubber-to-metal bonds

The metal part ol rubber-to-metal bonded products should not come into contact with the rubber of other products Any preservative used on the metal should be such that it will not adversely affect the rubber or the bond to such an extent that it does not comply with the product speclftation.

6.2.12 Proofed fabrics and rubber sheeting

Proofed fahocs and rubber sheeting less than approximately 1 m2 en area or less than approximately 2 m In length should be slored flat, ideally wilh the layers interleaved with a suitable matersal as specified in 5.2. Larger areas and longer lengths of material should be rolled, with the layers interleaved with a suitable material as specified in 5.2,

6.2.13 RotatIon of stocks

Pro&cts should be issued from stores in strict rotation so that the products remaining in store are those of most recent manulacture or delivery.

7 Inspection, testing and recording of data duting storage

7.1 RecordIng

A record should be kept of the test characteristics of items stored. Such records should include an indication of the acceptable confidence interval of the mean for each parameter tested where the test conducted provldes a numerical result.

NOTE In flas regard, reference to ISO 2602 arxl ISO 3207 is advised.

A record should also be kept of the following:

— the quantity of each item stored, the date of initial packaging, and the date it was put into store:

— the date of any subsequent repackagmg (see 7.4);

— the manufacturers batch number [see 5.3 9)):

— the quantity of items that are a representative sample of those items.

7.2 Inspection

7.2.1 Inspection before extension storage

Before any items are to be stored for any extension storage penod (see 7.3.2), representative samples of each type should be selected for inspection at the end of the appropriate initial storage periad. Items should not be laid on concrete floors or other rough surfaces or In areas susceptible to contamination by grit.

baispection should be in accordance with the relevant prodct specification or. where the relevant specification does not make such provision, the minimum visual inspection procedures In 7.2.2 should apply.

ISO 2230 pdf download – Rubber products -Guidelines for storage