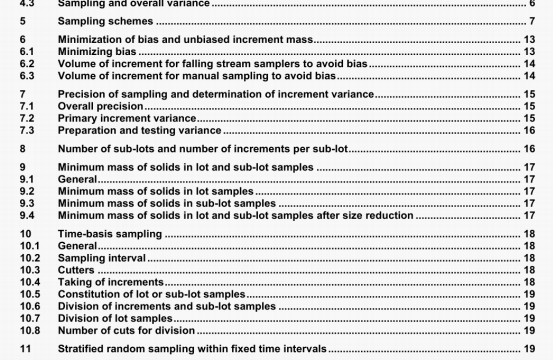

ISO 20904 pdf download – Hard coal-Sampling of slurries.

f) Determine the variability of the coal and the variance of preparation and testing for the quality characteristics under consideration (see Clause 7).

g) Determine the number of sub-lots and the number 01 mcrements per sub-lot required to attain the desired precision (see Clause 8),

h) Determine the sampling Interval in minutes br time-basis Systematic sampling (see Clause 10) or stratified random sampling within fixed time Intervals (see Clause 11).

i) Take slurry increments at the intervals determined in step h) during the whole period of handling the lot.

During sampling operations, sub-lot samples may be combined to constitute a single lot sample for analysts

(see Figure 2). Alternatively, increments taken tron’i sub-lots may be used to constitute sub-lot samples for

analysis, which also improves the overall precsion of the measured quality characteristics of the lo (see

Figure 3). Other reasons for separate preparation and analysis of sub-lot samples are

— for convenience of materials handling:

to provide progressive information on the quality of the lot:

— to provide reference or reserve samples after divlson.

Each increment may also be analysed separately (see Figure 4) to determine the increment variance of quality characteristics of the lot. In addition, it is recommended that the precision achieved ii practice should be checked on an ongoing basis by duplicate sampling where alternate increments are diverted to lot samples A and B (see Figure 5) from which two test samples are prepared and analysed A substantial number of sample pairs (preferably at least 20) is required to obtain a reliable estimate of precision

In most situations, it is not necessary to crush or pulverise the solids in the slurry increment to allow further division, since most slurries contain only fine particles However, if the particles are coarse and particle-size reduction is required to allow further division, it is necessary to re-determine the minimum sample mass for the lot using the new nominal top size of the crushed solids (see Clause 9).

The initial design of a sampling scheme for a new plant or a slurry with unfamiliar characteristics should. wherever possible, be based on experience with similar handling plants and material types Alternatively, a substantial number of increments, eg. 100, can be taken and used to determine the quality vaflation of the contained sotids. but the precision of sampling cannot be determined a pnon.

Sampling of slurries in stationary situations, such as a settled or even a well-stirred slurry in a tank, holding vessel or dam, is not recommended and is not covered in this International Standard.

If neither of these values is available, a value of I = 20 for ash content can be assumed initially and checked. after the sampling has been camed out, using one of the methods described in ISO 1 3909-7

7.3 Preparation and testing variance

The value of the preparation and testing variance. I . required for the calculation of the piecis,on using Equation (11) can be obtained by either

a) direct determination on the slurry to be sampled using one of the methods descflbed in ISO 13909-7, or

b) assuming a value determined for a similar tiurry from a similar sample preparation scheme. If neither of these values is available, a value of 0,2 for ash content can be assumed initially and checked. after the preparation and testing has been carried out, using one 01 the methods described In ISO 13909-7.

8 Number of sub-lots and number of increments per sub-lot

The number of increments taken from a lot in order to achieve a particular precisIon is a function of the variability of the quality of the slurry In the lot irrespective of the mass of the lot. The lot may be sampled as a whole, resulting In one sample, or divided into a number of sub-lots resulting in a sample from each. Such divis1on can be necessary in order to achieve the required precision.

There may be other practical reasons for dividing the lot:

a) for convenience when sampling over a long period;

b) to keep sample masses manageable.

After determining the minimum number of sub-lois required for practical reasons, estimate the number of increments in each sub-lot for a desired precision from Equation (12). obtained by transposing Equation (11).

ISO 20904 pdf download – Hard coal-Sampling of slurries