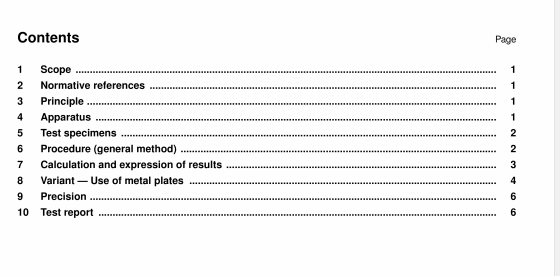

ISO 1926 pdf download – Rigid cellular plastics – Determination of tensile properties.

8 VarIant — Use of metal plates

8.1 General

This variant differs troni the general method in that the ends ot the lest specimens are modified to allow them to be bonded to reinforcing metal plates.

Consequently, follow the directions given in Clauses 4 to 7, taking into account the following modifications,

8.2 Apparatus

8.2.1 Test machine, designed in such a way that

a) a test specimen having the shape and dimensions shown in Figure 2 can be held between two clamps each conrlsing two cylinders of diameter 30 mm orthogonal to the plane of the test specimen, one of the damps being fixed and the other movable, the force being transmitted equatly by each of the four cylinders;

b) see Clause 4:

c) see Clause 4;

d) seeClause4.

8.2.2 Metal plates. ot the form and &mensions shown in Fiire 2; four are required for each test specimen subecled to the test. (Plates of aluminium alloy or anodized aluminium are likely to be satislactory.)

8.2.3 AdhesIve, for fixing the metal plates to the test specimens. It shall be such that the shear strength of the adhesive film is greater than that of the cellular material under test. so as to avoid any slipping of the test specimen on the plates. Preliminary tests shall make it possible to verify that the elongation of this film can be disregarded in the determination of the elongation et the test specimen. In addition, the adhesive film shall not appreciably modify the characteristics of the cellular material. (An epoxide resin base adhesive Is likely to be satisfactory.)

8.3 Test specimens

8.3.1 Dimensions

The test specimens shall have the shape and the &mensions shown in Figure 2.

8.3.2 PreparatIon and conditioning

Bond four metal plates to the ends ol each test specimen so that the plates exactly cover the ends of the specimen, as shown in Figure 2, in order to reinforce them.

Use a bonding jig which will hold the metal plates firmly in place, face to face, during bonding and during the setting time.

For condif toning of the test specimens. see 5.2.

10 Test report

The test report shall include the following intormation:a) a reference to this lnternational Standard;

b) the nature of the material tested;

c)the conditioning procedure used;

d)which of the two types of test specimen were used (if the variant described in Clause 8 was used, state clearly: “metal plates used””);

e) the number of test specimens tested;

f)where applicable, the direction of the tensile force in relation to the direction of anisotropy;

g)the individual results,calculated using the equations given in Clause 7, and their average;

h) the stress-strain curve;

i)any deviation from the method specified;

j)the date of the test.

ISO 1926 pdf download – Rigid cellular plastics – Determination of tensile properties