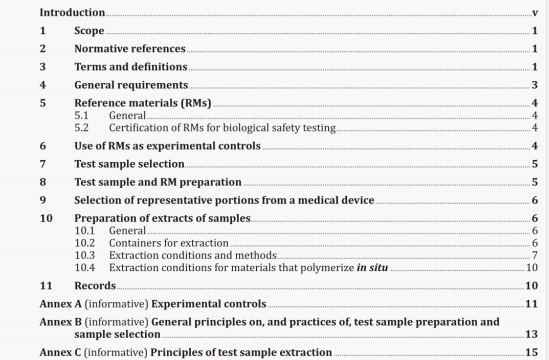

ISO 10993-12 pdf download – Biological evaluation of medicaldevices — Part 12: Sample preparation and reference materials.

Experimental controls shall be used in biological evaluations carried out in order to either validate a

test procedure or compare the results between materials, or both. Depending on the specifications of a

particular test, either negative controls, blanks or positive controls, or all three, shall be used.

NOTE The anie type ol control c.in br applicable to different tests and can ,illow cross-reference to other established materials and test methods. Additional guidance on the selection of experimental controls is given in Annex A. Use of positive controls for in vn’o testing might be affected by animal welfare regulations.

5 Reference materials (RM5)

5.1 General

RMs are established by Individual laboratories. The extent of chemical, physical and biological characterization is determined by the individual laboratory Commercially available articles may he used as RMs.

NOTE See also ISO Guide 35.

CRMs are selected for their high purity, critical characteristics, suitability br the intended purpose and general availability. The critical chemical, physical and biological characteristics shall be determined by collaborative testing in three or more laboratories and made available to the investigator by the distributor.

It is desirable for users to obtain a commitment from suppliers of RMs or CRMs stating that these materials will be available to the user for at least five years. A second but less desirable option is for the source of the RM or CRM to publish an “open formulation” for the material. I.e. publication of the source materials and details of the processing needed to ensure uniform hatches of the KM.

5.2 Certification of RMs for biological safety testing

Qualification of an KM is a procedure that establishes the numerical or qualitative value of the biological response of the material under specified test conditions, ensuring reproducibility of the response either within laboratories or between laboratories, or both. The range of biological responses associated with the material shall be established through laboratory tests.

NOTE See also ISO 17034.

Suppliers of RMs shall certify the materials. The supplier determines the extent of chemical and physical characterization that Is performed. The individual laboratories that use the RM shall Identify the biological characterization necessary to qualify an KM for a specific test or procedure. Commercially available materials may be used as KMs, provided they are certified and qualified.

Certification of a KM isa procedure that establishes the numerical or qualitative value of the biological response of the material tinder the specified test conditions. This process serves to validate the testing of the material for that particular response and results In the Issuance of a certificate. The biological response of the material shall be established through interlaboratory tests.

6 Use of RMs as experimental controls

RMs or CRMs shall be Llsed iii biological tests a cuuuol materials to demonstrate the suitability of a procedure to yield a reproducible response, Ic. positive or negative, or both. Any material used in this way shall be characterized with each biological test procedure for which the use of the material Is desired. A material characterized and then certified for one reference test method or response, for example, delayed-type hypersensitivity shall not be used as an RM for another, for example, cytotoxicity. without additional validation,

NOTE The use of an RU will facilitate the comparability of the response between laboratories and help assess reproducibility of the test performance within Individual laboratories. For comparison of the biological response, it is desirable to use RMs having a range of responses, e.g. minimum, intermediate or severe.

RMs used as experimental controls shall meet the established quality assurance procedures of the manufacturer and test laboratory. They shall be identified in relation to source, manufacturer, grade and type. RMs are processed as described In Clause 8.

When RMs are used as experimental controls, they shall be in the same material class as the test sample. i.e. polymer, ceramic, metal. colloid. However, pure chemicals may be used as experimental controls for mechanistically-based test procedures, for example. genotoxicity and immune delayed- type hypersensitivity assays.

ISO 10993-12 pdf download – Biological evaluation of medicaldevices — Part 12: Sample preparation and reference materials