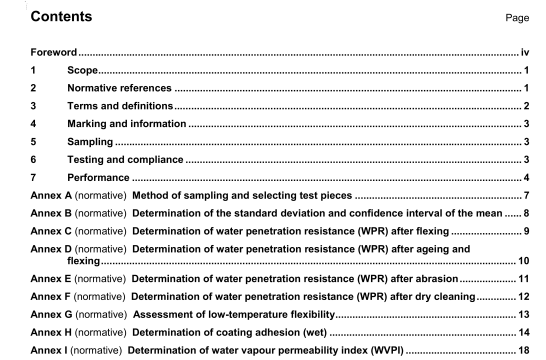

ISO 8096 pdf download – Rubber- or plastics-coated fabrics for water-resistant clothing – Specification.

Ci Cut five test pieces of a size suitable for conducting both flexing and water penetration resistance tests on the same test piece (e.g. generally of 220 mm x 190 mm). Test each of the five test pieces in acconiance w’iltiC.2andC.3.

C.2 Mount the test piece in a crumple/flex apparatus as described in method C of ISO 7854:1995 with the coated surface (that designated as such by the supple) outermost and carry out the test for 9000 cycles.

C.3 Remove the test piece from the crumple/flex apparatus and determme the water penetration resistance In accordance mth ISO 811. with the outer surface (that designated as such by the supplier) exposed to the water. Note and record any delamination which may have occurred (see 7.3).

CA If any test piece exhdits seepage or leakage during the determination of waler penetration resistance. repeat the test on five fresh test pieces.

D.1

Expose five test pleces measuring 300 mm x 250 mm to the accelerated-ageing procedure appropriate to the coating polymer as given in Table 1.

D.2

Where required by Table 1, subject the test pieces to three wash cycles in accordance with washing procedure 6A of ISO 6330:2000, using detergent (without optical brightener), followed by drying procedure C .

(dry fiat).

D.3 Condition the test pieces in atmosphere A B or C as defined in ISO 2231.

D.4 From each aged test piece, cut a specimen for crumple flexing having dimensions of 220 mm x 190 mm.

D.5 Mount the specimens in the crumple/flex apparatus in accordance with method C of ISO 7854:1995, coated surface (that designated as such by the supplier) outermost, and conduct the test for 9 000 cycles.

D.6 Remove the specimens from the crumple/lex apparatus and note and record any delamination which may have occurred.

D.7 Measure the water penetration resistance of each specimen in acordance with IS0 811, outer surface (that designated as such by the supplier) exposed to the water. Nole and record any delamination which may have occurred (see 7.3).

D.8 If any specimen exhibits seepage or leakage during the determination of water penetration resistance, repeat the test on five fresh test pieces taken, if possible, from the original sample.

6.1 Select five test pieces suitable for conducting hydrostatic-head tests in accordance with ISO 811. Mark the face and reverse sides of the test pieces for identification.

6.2 Fold three test pieces with the outer surface (that designated as such by the supplier) innermost as follows.

a) make the first fold across the centre of the test piece so that the fold is parallel to the selvedge or machine direction;

b) make the second fold across the centre of the folded test piece so that the second fold lies at nght angles to the selvedge or machine direction,

6.3 Fold the remaining two test pieces in the same way as described Ii 6-2 a) and b), but with the outer

surface (that designated as such by the supplier) outermost

6.4 Place the folded test pieces in an atmosphere maintained at (-30 ± 2) C and cover with a weight-piece

(pre-cooled to this temperature) so that a pressure of 4 kPa as exerted over the folded face of each test piece.

NOTE A 11 3-rn-diameter test piece so folded presenis an area of apprommalely 2510 mm2. A weight-piece of 1.022 kg sigierposed on this area would exert a pressure of 4 kPa A test piece originally measuring 150mm 150mm folded in accordance with 62 a) and b) woeld present an area of 5625 nwn2 To achieve a pressure 0(4 kPa over the area, the weight-piece would have to have a mass of 2.27 kg.

6.5 Expose the test pieces to this low-temperature environment for (48 ±2) h.

6.6 Remove the weight-piece and, wearing insulated gloves or using another suitable means of avoiding heating the test pieces, unfold each test piece inside the cold chamber. Immediately remove the unfolded test pieces from the cold chamber and place each, opened out fully flat, with the surface which formed the inside of the folded test piece against a flat, hard, horizontal surface. Cover with a weight-piece of 2,5 kg, placed over the whole of the test piece, and keep In an atmosphere maintained at (20i. 2) C and (65 ± 5) % r.h. for (24 ±2) h.

6.7 On completion of this conditioning period, remove the weight-piece, examine the test piece without magnification for signs of cracking or delamination and then supiect each test piece to a hydrostatic-head test In accordance with ISO 811. up to the pressure specified for the grade In Table 4. The surface which formed the inner side of the folded test piece shall be mounted uppermost (i.e. not in contact with the water). Note and record any delamination or cracking which may have occurred (see 7.3 and 6.3).

G.8 If, in 6.7, any test piece fails the requirement in terms of one particular direction of folding, the repeat tests required by 6.3 shall be carried out on test pieces folded in that particular direction.

ISO 8096 pdf download – Rubber- or plastics-coated fabrics for water-resistant clothing – Specification