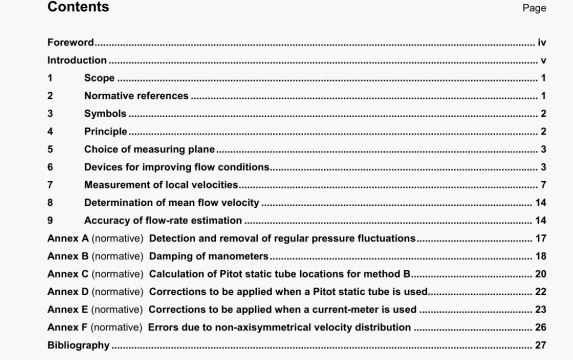

ISO 7194 pdf download – Measurement of fluid flow in closed conduits -Velocity-area methods of flowmeasurement in swirling or asymmetricflow conditions in circular ducts bymeans of current-meters or Pitot statictubes.

6.2.2 Type B — Sprenkle straightener (see Figure 3)

The Sprenkle straightener consists of three perforated plates In series, and is particularity effective in eliminating asymmetry. It does, however, have a high head loss (about 15 velocity heads) but two plates or even one plate (with head losses of about 10 and five velocity heads, respectively) can be used if such a high head loss is not acceptable. Although they cannot completely eliminate such severe asymmetry as can the three plates, they are often sufficient for disturbances such as a single bend. Perforated plate straighteners have some effect in reducing swirl, but are not designed for this; if, therefore, swirl is the dominant type of irregularity in the velocity distribution, one of the other straighteners should be used.

6.2,3 Type C — Tube bundle straightener (see Figure 4)

The basic purpose of the tube bundle straightener is to eliminate swirl, but it also has some effect in reducing asymmetry. There shall be a minimum of 19 tubes, with a length of at least 20 times the diameter of the tubes. and each tube shall have a maximum diameter of 1)15. The head loss of this straightener depends on the size and length of the individual tubes, but is typically about five velocity heads.

6.2.4 Type D — AMCA straightener (see Figure 5)

The AMCA straightener is useful only in eliminating swirl; it does not improve asymmetric velocity distributions. Its dimensions are given in Figure 5, and It has a very low head loss, normally about 0.25 times the velocity head.

6.2.5 Type E — Etoile straightener (see Figure 6)

The étoile straightener is again designed only to eliminate swirl, and Is of no assistance with asymmetric velocity distributions. The eight radial vanes should be chosen to provide adequate strength, but should not be unnecessarily thick. This straightener should have a length equal to 2D. It has a very low head loss, similar to that of the AMCA straightener, but has the advantage that it is much easier to manufacture. In addition, it allows the static pressure to equalize radially as the flow passes through it, unlike the AMCA, tube bundle or Zanker straighteners which can induce significant variation in static pressure across the pipe downstream of them.

7.3.2 Method B

This method may be used only when the angle which the local velocity makes with the axis of the pipe is less than 400 at all of the measuring positions across the traverse plane.

After determining the angle of swirl with a yaw probe at each of the measuring positions, one of the Pitot static tubes specified in ISO 3966 shall be installed at each measuring position in turn. It shall be installed in such a way that the axis of the head is parallel to the local flow direction in each case. The differential pressures are then noted.

With this method, the radial positions of the nose of the Pitot static tube are different from those of the yaw probe whenever swirl is present. They are not located along a diameter of the duct, but follow a curved path. This is illustrated in Figure C.1 which shows typical positions of the Pitot static tube when axisymmetrical swirl occurs.

When prescribed locations of the Pitot static tube have to be used (as with the log-linear or log-Chebyshev integration techniques), it is necessary to calculate the positions at which the Pitot static tube heel has to be located in order that the nose is at these radial positions. Conversely, if the numerical or graphical integration technique is used, it is necessary to calculate the radial positions at which the Pitot static tube nose will be located in terms of the radial positions chosen for the heel. (See Equation (C.1).J

When method B is used, the maximum value of the local swirl angle limits the maximum usable diameter of the Pitot static tube head. Figure 10 shows the relationship between the maximum permissible value of the ratio, dID, and the maximum local swirl angle, where d is the diameter of the Pitot static tube head and D the diameter of the duct.

The axial velocities shall be computed for each position from.

ISO 7194 pdf download – Measurement of fluid flow in closed conduits -Velocity-area methods of flowmeasurement in swirling or asymmetricflow conditions in circular ducts bymeans of current-meters or Pitot statictubes