ISO 6249 pdf download – Petroleum products- Determination of thermal oxidation stability of gasturbine fuels.10.8.3 DIsconnect reservoir. Measure the amount of spent fluid pumped during the test and reject the test if the amount is less than 405 ml. Discard fuel to waste disposal.

10.8.4 Disassemble the remainder of the equipment in accordance with the manufacturer’s instructions. Clean the sparger (51) wIth appropriate solvent (5,) to prevent transfer of contamination.

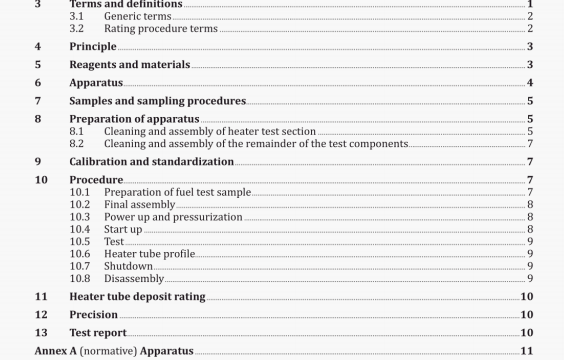

11 Heater tube deposit rating

11.1 Rate the deposits on heater tube In accordance with Annex B. C. D or E

NOTE For detailed descriptions on how these procedures work. see ASTM D3241151.

11.2 Return tube to original container, record data, and retain tube for visual record, if required.

12 Precision

It is not possible to specify the precision of this test method because it has been determined that test method results cannot be analysed by standard statistical methodology.

13 Test report

The test report shall contain at least the following Information:

a) sufficient details for complete identification of the fuel and the heater tube tested;

b) reference to this document. I.e. ISO 6249:2021;

c) the heater-tube control temperature;

d) the heater-tube deposit rating(s) or measurements and the rating methodology (see ILl);

e) the pressure differential across the test filter at the end of the test or the time required to reach a pressure differential of 3,33 kPa (25 mmHg);

f) if the normal test time of 150 minis not completed, e.g. if the testis terminated because of pressure drop failure, the test time that corresponds to the heater deposit rating;

g) the volume of spent fuel at the end of a normal test (this will be the amount on top of the floating piston or the total fluid in the displaced water receptacle, depending on the model used);

h) any deviation, by agreement or otherwise, from the procedure specified;

I) the date of the tesL.

NOTE Either the tube rating, or chinge In pressure, or both. are used to determine whether a fuel sample passes or fails the Lest at a specified tcsI temperature.

A pressure gauge or transducer shall be used to measure and allow monitoring of the total system pressure. The gas-pressurized systems shall be run closed after pressurization, whereas the hydraulically pressurized systems shall have a relief valve through which the Iluld passes in a constant icak throughout the test. For the relief-valve control to operate uniformly for any fuel, a displacement cell shall be used where the spent fuel enters the top, displacing water out the bottom and through the relief valve.

NOTE 2 SInce the valve sees only water. It works consistently.

A.7 Differential-pressure measurement

The differential pressure (P) across the test filter shall be measured during the test using either a mercury manometer with a possible strip-chart pressure-recording option, or an electronic pressure transducer (see Figure A.3).

By-pass and air bleeding are essential to ensure proper use of these differential measuring devices. The former allows the fuel flow to by-pass the filter.

Air bleeding shall be used to remove air or nitrogen that at times may become trapped in the cell chambers. The manometer output shall be read as the height of the column of mercury and the transducer output shall be displayed digitally.

A.8 Calibration of the differential-pressure transducer cell

A.8.1 To confirm that the OPT model Is reading correctly, perform the following check using a standardization kit (levelling bottle, special tube fitting and detailed instructions) supplied with each equipment,

NOTE The calibration of the transducer system is internal and not normally accessible to the user. Calibration by the manufacturer ensures that the differential-pressure transducer (OPT) cell gives an equivalent pressure reading to that which would result from using the mercury manometer. When a static check Is made to confirm that the OPT cell Is funct lonal, the reading includes the offset tare for the flow compensation and the bias due to use of a mercury/kerosene manometer, The readings, therefore, are only relative but are expected to be consistent for each equipment.

A.8.2 Select a typical fuel to be used in the standardization, and determine its density to three digits, In kilograms per cubic meter, by weighing, to the nearest 1 mg, a 10.0 ml pipette portion. Ensure that the fuel temperature is within approximately 10 °C of the working temperature at which the OPT is to be checked.

A.8.3 Attach the fittings of the standardization kit to the equipment and fill It with the standardization fuel. Remove the air from the transducer system in accordance with the kit instructions.

The process of removing air from the system and replacing any residual fuel with the standardization fuel is essential to the procedure.

ISO 6249 pdf download – Petroleum products- Determination of thermal oxidation stability of gasturbine fuels