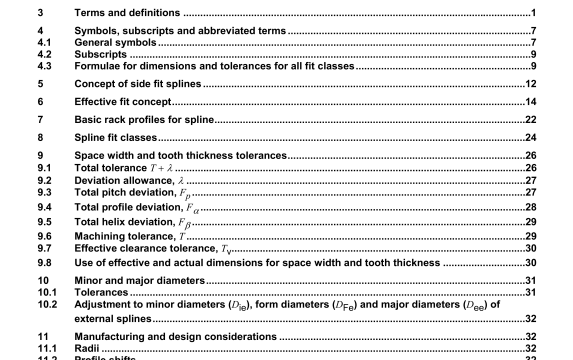

ISO 4156-1 pdf download – Straight cylindrical involute splines —Metric module,side fit— Part 1: Generalities.

10.2 Adjustment to minor diameters (0w). form diameters (Fe) and major diameters (D) of external spllnes

When fundamental deviation d, e and fare applied to external splines, it is necessary to adjust the major, font and minor diameters. When applying is and k classes, the minor and form diameters only are adjusted. see formulae and notes In Table 1.

11 Manufacturing and design considerations

11.1 Radii

External splines may be produced by generating with a pinion-type snaper cutter or a hoc, or by cutting with a no-generating motion using a tool formed to the contour of a tooth space. External spines are also made by cold forming, and in these cases are usually of the fillet root design. Internal splines are usually produced by broaching. by torn, cutting, or by generating with a shaper cutter. Even when full-tip radius tools are used, each of these cuttlig methods produces a fillet contour with individual characteristics. Generated spline fillets are curves related to the prolate epecyclold for external splines and the prolate hypocycloid for Internal spines. These filets have a minwnum radius of curvature at the point where the fillet is tangent to the external spline minor diameter circle or the internal spline major diameter circle, and a raply increasing radius of curvature up to the point where the fillet becomes tangent to the involute profile.

The values ii Table 12 may be used as minimum radii of curvature for stress calculations and specified as the minimum fillet radius. These values are based on the fillet radius shown on the basic rack profiles. For cutting of internal and external splines by generating. with the same pinion-type shaper cutter, the tool design will have to be made according to the dimensions of the internal splines to be obtained.

ISO 4156-1 pdf download – Straight cylindrical involute splines —Metric module,side fit— Part 1: Generalities