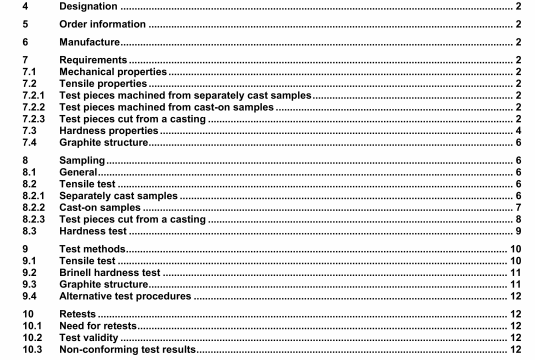

ISO 185 pdf download – Grey cast irons -Classification.

3.2

relevant wall thickness

section of the casting, agreed between the manufacturer and the purchaser, to which the determined mechanical properties apply

4 Designation

The material shall be designated as given it either Table 1 or Table 2. The designation system is given in

lSO/TR 15931.

5 Order information

The following information shall be supplied by the purchaser.

a) the complete designation of the material.

b) any special requirements which have to be agreed between the manufacturer and the purchaser. All agreements between the manufacturer and the purchaser shaM be made by the time of acceptance of the order

6 Manufacture

The method of producing grey cast iron and its chemical composition shall be left to the discretion of the manufacturer, who shall ensure that the requirements of this Intemational Standard are met for the material grade specified in the order.

NOTE For gray caM wore to be used in special applications, the chemical composition and heal treatment may be the sub,ect of an agreement between the manufacturer d the purchaser.

7 Requirements

7.1 Mechanical properties

The order shall wecify. in an unambiguous manner, whether the tensile strength measured on separately cast samples, or the Brinel hardness measured on the casting. is the characterizing property. If it does not do so, then the manufacturer shall characterize the material according to tensile strength.

7.2 Tensile properties

7.2.1 Test pieces machined from separately cast samples

The tensile properties of the eight grades of grey cast iron specified by tensile strength, when measured in accordance with 9.1 usIng test pieces machined from separately cast samples, shall be in accordance with the requirements of Table 1

The number in position 3 of the designation Is the minimum tensile strength of the grade. The maxsmxn tensile strength & the grade is the minimum value plus 100 N/mm2.

7.22 Test pieces machined from cast-on samples

The tensile properties of test pieces machined from cast-on samples, for the eight grades of grey cast won defined by tensile strength, shall be in accordance with the requirements of Table 1.

7.2.3 Test pieces cut from a casting

If applicable, the tensile properties of test pieces cut from a casting. for the eight grades of grey cast iron defined by tensile strength, shall be agreed between the manufacturer and the purchaser, and these tensile properties shall be in accordance with the requirements In the agreement.

Samples of other dimensions, and using other casting procedures, may be agreed between the manufacturer and the purchaser far the purpose of representing the properties of particular castings (an indication of the likely values of tensile strength is given in Figure C.1).

Samples shall be made from the metal used to produce the castings wtich they represent and during the same period as when the castings are made.

The frequency of casting the sepwately cast samples shall be In accordance with the In-process quality assurance procedures adopted by the manufacturer.

The samples shall be removed from the mould at a temperature 500 C.

NOTE By aeement between the manufacturer and the purchaser, samples may be removed from the mould at a temperature 500 ‘C, if the castags are also to be removed from the moulds at this higher temperature.

8.2.2 Cast-on samples

The test pieces used for the tests specified in Clause 7 shall be machined from a cast-on sample, as indicated in Figures 2 or 3. The test pieces shall be in accordance vAth 7.2.2. The type of sample shal be chosen in such a way as to provide approximately the same cooling conditions as for the casting to be represented. The type of sample, and the location of the sample on the casting, shall be agreed between the manufacturer and the purchaser, If there is no such agreement, the manufacturer shall decide on the type of sample and it shall be located at a representative position on the casting.

Cast-on samples should be used only when a casting is more than 20 mm thick and the mass is more than 200 kg.

ISO 185 pdf download – Grey cast irons -Classification