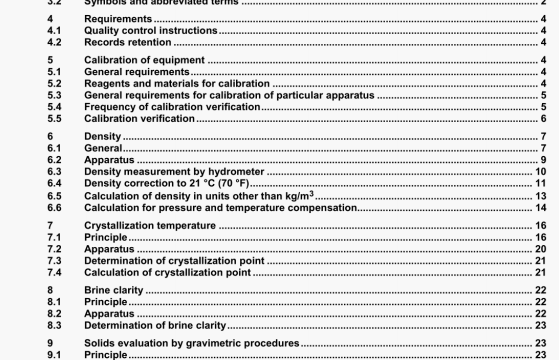

ISO 13503-3 pdf download – Petroleum and natural gas industries一Completion fluids and materials一- Part 3: Testing of heavy brines.

7.1 Principle

7.1.1 This clause descrties a method for the measurement of crystallization temperatures of brines used in completion, workover and drilling operations.

7.1.2 Three different crystallization temperatures are often quoted for the same brine because of the nature of the brine cooling curve. The following defines the three crystallization temperatures, discusses the practical significance of each crystallization temperature, and explains the difference between crystallization of salt crystals from a brine and the freezing of water from a brine.

7.1.3 The actual crystallization temperature of brine is that temperature at which a solid will begin to form from the solution if given sufficient time and proper nucleating conditions. The solid can be either salt or fresh water (ice).

7.1.4 The crystallization temperature for normally formulated brine is the temperature at which the brine is saturated with one or more salts that it contains. At this temperature, the solubility of the least soluble salt is exceeded and it crystallises as the salt or salt hydrate. Cooling the brine below the crystallization temperature results In formation of additional salt crystals. Brine having a crystallization temperature below the lowest anticipated operating temperature is recommended, in order to prevent crystallization of the brine during use.

7.1.5 Precipitation of salt crystals in brine at or below the crystallization temperature can lead to a number of problems. Rapid plugging of titration units can occur. If salt crystals settle in the tank, the density of the brine pumped downhole can be insufficient to control formation pressures. As additional crystals form, brine viscosity can increase. The viscosity can become so high that the brine appears to be a frozen solid. This can cause line plugging. fluid in tanks becoming soid. and pump seizures. Sufficient heating and agitation of the bflne redissolves the crystals with no permanent ctiange In the brine properties.

7.1.6 SInce salt crystals should have a smaler specific volume than the brine, the brine will not expand in volume during crystallization, and should not cause ruptured lines, valves or pump heads, which can occur when water freezes. However, low concentrations of salt solutions wil expand and can lead to equipment failure.

When using an electronic cooling system, follow the manufacturer’s recommended test procedure.

7.2.4 Seeding material. 0.1 % mass fraction of an inert, msoluble nucleating agent.

See 7.1.12. lIsa approximately 0,039 seeding material, equivalent to a few grains of salt, for 25cm3 of brine.

7.2.5 Organic seeding marker

7.3 Determination of crystallization point

7.3.1 Measure approximately 25 an3 of the brine to be tested Into the sample container. Add the nucleating agent to the sample Place the sample container insade the outer container and place both in the cooling bath with the temperature-measuring device probe inserted in the brine.

7.32 Cool the sample slowly to minrnise super-cooling. Stir the brine and record the temperature decrease of the sample. The temperature of the brine will decrease steadily until crystals begin to form. Record the minrn’ium temperature reached before crystallization as the FCTA temperature.

7.3.3 Record the maximum temperature achieved immediately after crystallization has occurred. The temperature should slabilise briefly (10 s to 20 s). If the temperature does not stalalise. or if a large amount of super-cooling is evident (TCT minus FCTA is greater than 3 ‘C (5 ‘F)). repeat the test on the same sample. For the repeat test, the sample should be warmed above the LCTD point, but no more than 4 ‘C (8 ‘F) higher than the LCTD point.

7.3.4 Discontinue cooling the sample by removing the sample container from the bath or increasing the temperature setting of the cooling plate or bath. Allow the sample to wami, while observing for the drssolubon of crystals. When all crystals have dissolved, record the temperature as the LCTD.

7.3.5 Repeat 7.3.2 tlvough 7.3.4 at least three twnes using the same sample. The sample should be warmed above the LCTD but no more than 4 ‘C (8 ‘F) higher than the LCTD point.

7.4 Calculation of crystallization point

Calculate average readings of the three or more tests from 7.3.5. Do not include any data in which super-cooling exceeds 3 ‘C (5 ‘F) below the TCT point. Report the temperatures for FCTA.

ISO 13503-3 pdf download – Petroleum and natural gas industries一Completion fluids and materials一- Part 3: Testing of heavy brines