ISO 12743 pdf download – Copper, lead, zinc and nickel concentrates -Sampling procedures for determination of metal and moisture content.

a) each primary increment shall be subjected separately 10 divisIon (according to the rules of division) and determination of its quality characteristics, or

b) primary increments shall be subjected to constant mass division, prior to combining into subsamples or a lot sample.

Primary increments and subsamples should not be combined into a single sample for the lot, unless the composite sample can be adequately mixed (see 15.3),

For the determination of moisture content, it is recommended that a moisture subsample be constituted for each sub-lot, This will not only reduce the total variance, but it will also minimize loss of moisture and hence bias.

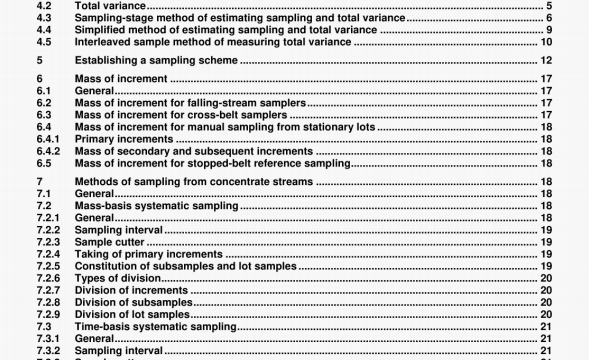

7.2.6 Types of division

Two types of division are appkcable to mass-basis sampling as follows.

a) Constant-mass division, which is a method of obtaining divided increments, subsarnples o Pot samples having almost uniform mass, regardless of the variation in the masses to be divided. Cutter-type dividers having variable cutting frequencies can be used for this type of division (see 15.4.6).

b) Proportional division, which is a method of obtaining divided increments. subsamples or of samples having masses proportional to the varied masses to be divided Rotary sample dividers can be used for this type of division (see 1 54.5).

NOTE Cutter-type dividers may lead to moisture ss. so are not recommended for division of molsliie sanIes,

7.2.7 DivisIon of Increments

Where increments require division and subsamples or a lot sample are constituted from the divided increments, division shall be carried out as follows (see Table 4):

a) if the coefficient of variation of the increment masses is 20 % or less, either constant-mass or proportional division shall be used.

b) It the coefficient of variation of the increment masses is greater man 20%. division shall be canted out on an increment-by-increment basis using constant-mass division.

7.2.8 DivIsion of subsamples

Where subsamples are divided and a lot sample is constituted from the divided subsamples. division shall be carried out as follows (see Table 4):

a) It the coefficient of variation of the subsample masses is 20 % or less, and the subsamples consist of an equal number of increments, either constant-mass or proportional division shall be used

b) lithe coefficient of variation of the subsample masses is greater than 20%, and the subsamples consist of an equal number of increments, constant-mass division shall be used

C) lithe subsamples consist of dill erenf numbers of increments, proportional division shall be used.

7.2.9 Division of lot samples

When a lot sample is divided, either constant-mass or proportional division shall be used,

8 Mechanical sampling of concentrate streams

8.1 General

There are a number of different mechanical sampling devices, and hence it is riot possible to specify any particular type which should be used fo specific sampling applications. However, the sampling device selected must pass a bias lest, i.e. it shall be unbiased In this respect, special care shall be taken to minimize change in moisture content, e.g. by minwnizing vertical drops, eliminating air flows, and avoiding low flow rates. Degradation of the constituent particles shall also be minimtzed it particle size determination is to be carried out on the sample. Annex C shows typical examples of sample cutters in common use and should be taken as a guide In choosing suitable equipment.

This International Standard deals only with mechanical sampling devices that take a complete cross-section of the concentrate stream. Sampling devices taking only part of the stream shall only be used it it can be shown. using ISO 13292. that there is no significant bias.

8.2 DesIgn of the samplIng system

8.2.1 Safety of operators

From the initial stage of design and construction of a sampling system, &ie consideration shall be given to the safety of operators. Applicable safety codes of the Regulatory Authorities shall be respected.

8.2.2 LocatIon of sample cutters

When choosing the location of sample cutters, the following criteria shall apply.

a) Sample cutters shall be located at a point providing access to the complete concentrate stream.

b) Sampling shall be performed close to the weighing point in space arid time.

c) Sampling should be performed at a point wi the handling system where there Is minimal segregation of the concentrate stream, and where there is minimal risk of errors due to a systematic variation in flow rate or quality.

Basic requirements are to be taken into account from the early stages of design, construction and installation of the system, as well as during the operation and maintenance of the plant. To permit the bias checks specified In 8.2.5. provision should be made for stopped-bell reference sampling adlacent to the sample cutter.

ISO 12743 pdf download – Copper, lead, zinc and nickel concentrates -Sampling procedures for determination of metal and moisture content