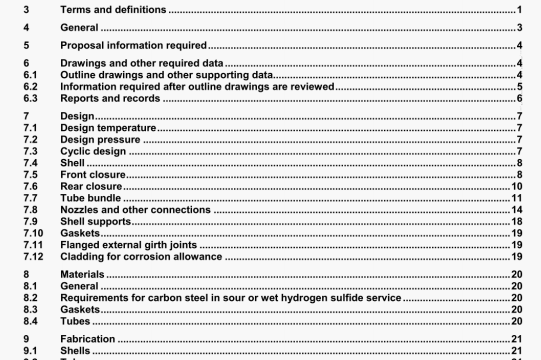

ISO 12212 pdf download – etroleum, petrochemical and natural gas industries – Hairpin-type heat exchangers.

7.7.4.4 Provision shall be included to protect tubesheet sealing surface from damage during bundle

insertion or removal.

77.5 Tube-to-tubasheet joint

The tube-to-tubestieet joint shall be in accordance with the TEMA standard unless otherwise specified by the

purchaser.

7.8 Nozzles and other connections

7.8.1 Flanges shaM be in accordance with the pressure design code unless otherwise specified by pLichaser.

7.8.2 Connections DN 40 (NPS 1112) and Larger shall be flanged unless otherwise specified by the pL%chaser.

7.8.3 Connection sizes of DN 32 (NPS 1.114), ON 65 (NPS 2.1(2). ON 90 (NPS 3.1(2) or DN 125 (NPS 5) shall not be used.

7.8.4 If welded connections are specified, they shall be bevelled.

7.8.5 Non-flanged connections smaller than DN4O (NPS 1112) shall be forged couplings with an appropriate rating. for example equivalent to ASME 816.11 class 6000, or shall be integraly reinforced welding fittings with appropriate tapered threads, for example equivalent to ASME 8120.1. and shall comply with the pressure design code, Threaded connections shaM not be used in hydrogen, sour or wet hydrogen sulfide service. This mciudes auxiliary connections such as vents, drains. mstrument connections and chemical cleaning connections.

7.8.6 Flanged connections shall be of one of the following types:

a) forged integrally flanged:

b) pipe or forged cylinder welded to forged welding-neck flange:

C) pipe welded to a forged slip-on flange, except as noted in 78.7,

7.8.7 Slip-on flanges shall not be used in any of the following conditions:

a) for design pressure exceeding 2 100 kPa (ga) (300 psig):

b) for design temperature exceeding 400 C (750 F):

c) for corrosion allowance exceeding 3mm (1/8 in);

d) in hydrogen service, sour, or wet hydrogen sulfide service:

e) in cyclic service.

7.8.8 When specified by the purchaser, the Fxo,ecbon of flanged connections shall allow the removal of through-bolting from either side of the flange without removing the insulation, This requirement does not apply to the interconnecting nozzles of stacked units. The insulation thickness shall be specified by the purchaser.

7.8.9 Integrally reinforced nozzles shall be clesigeed so that standard spanners (wrenches) fit the nuts without interference from nozzle neck reinforcement

7.8.10 All bolt holes for flanged or studded connections shall straddle centrelines,

7.9.2 When the fixed shell support of a removable-bundle heat exchanger is fixed to the shell, it shall be designed to withstand a longitudinal force equal to 150 % of the bundle mass applied at the heat exchanger bundle centreline, The shear stress for supports shall not exceed 40 % of the yield strength of the matenal.

7.9.3 Support material in direct contact with the shell shall be of the same nominal composition as the shell.

7.9.4 The lower shells of stacked removable-bundle heat exchangers shall be designed to carry the superimposed loads without suffering distortion that can cause binding of the tube bundles.

7.9.5 All units shall have at least one earthing lug, welded dwectty to a statable shell side comporteni

7.10 Gaskets

7.10.1 Spiral-wound gaskets, where used, shall be provided with a means to prevent over-compression and buckling.

7.10.2 Gaskets shall be of a one-piece design. Gaskets made integral by no more than two welds are acceptable.

7.11 Flanged external girth joInts

7.11.1 External girth joints shal be of through-bolted construction, unless otheiwise approved by the purchaser.

7.112 Minimum bolt diameter shall be 12mm (1/2 In).

7.11.3 SlIp-on flanges shall not be used as girth ftanges.

7.11.4 The gap between mating flanges after assently shall be not less than 3mm (1/8 In) and this gap shall extend within the boll circle to allow checking the flanges for radial distortion caused by an excessive bolt load.

7.11.5 Through-hardened washers shall be provided under nuts for all bolts having a diameter of 38 rrwn (1112 in) or larger unless hydraulic bolt tensioners are used. The washers shall be at least 6 mm (1)4 in) thick.

7.11.6 The purchaser shall specify if bolt-tightening devces WI be used. When used, the nozzles end/or girth flanges shall be designed to allow adequate clearance.

712 CladdIng for corrosIon allowance

7.12.1 If cladding (including weld overlay) is used, the cladding thickness shal be used only as corrosion allowance and not for pressure design.

7.122 The cladding thickness at the tube side face of a tubesheet shall be not less than 10 mm (3)8 in) when tubes are expanded only, and 5mm (3/16 in) when tubes are welded to the tubesheet. If grooves are use, the fIrst groove shall be within the tube side cladckng.

7.12.3 The cladding thickness on the shell side face of a tubesheet shall be not less than 10 mm (318 in).

7.12.4 Weld overlays shall have sufficient thickness to provide the specified chemical composilion to a depth of at least 1,5mm (1116 in).

ISO 12212 pdf download – etroleum, petrochemical and natural gas industries – Hairpin-type heat exchangers