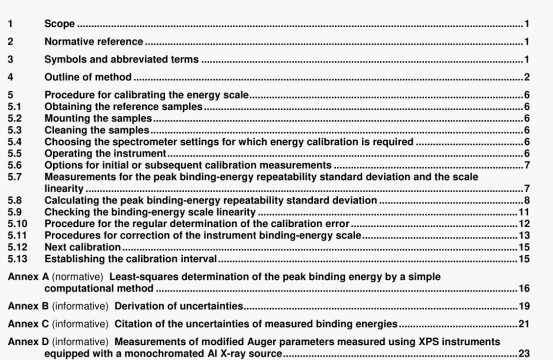

AS ISO 15472 pdf download – Surface chemical analysis—X-rayphotoelectron spectrometers—Calibration of energy scales.

NOTE It the samples appear to need clearing, a short cap In I % nitric and may be used for Cu and Ag with subsequent rinsing in distilled water, lithe Cu sample has been stored in the — for more than a tew days. the clp in nitric acid will make the sample cleaning, required later wi 5-3.1, much easier,

5.2 Mounting the samples

Mount the sampLes of Cu. Au and. ii appropriate, Ag on the sample holder or on separate sample holders, as appropriate, using faxing screws, or other metallic means, to ensure eiectncal contact: do not use double-sided adhesive tape.

5.3 CleanIng the samples

5.3-1 Achieve ultra-high vacuum and clean the samptes by ion sputtering 10 reduce the contamination until the heights of the oxygen and carbon Is signals are each less than 2% of the height of the most intense metal peak in each survey spectrum. Record a survey (widescan) spectrum for each of the samples to ensure that the only significant peaks are those of the required pure elements. The quality of vacuum necessary here is such that the oxygen and carbon is peak heights shall not exceed 3% of the heights of the most intense metal peaks by the time you have reached completion of 5.10 or at the end of the working day (wfichever is the earlier).

NOTE I hert-gas ion-sputtering conditions that have been found suitable for cleaning are I man of a 30 pA beam of 5 keY argon ions covering 1 cm2 of the sample.

NOTE 2 Example XPS spectra may be found an relerences (4) to (8) of the bibliograpiy

512 Try to conduct all relevant parts of this International Standard ii one working day. If more than one day is

required, confirm tile cleanness of the samples at the start of each days work.

5.4 Choosing the spectrometer settings for which energy calibration is required

Choose the spectrometer operating settings for which the energy calibration is reqared. The calibration xocedure from 5.4 to 5.13 shall be repeated for each X-ray source and combination of spectrometer settings of pass energy, retardation ratio, slits, lens settings, etc., tor which a calibration is required. Record the values of these settings in the speclrometer calibration log.

NOTE The designs ot spectrometers and their circuits vary, and a spectrometer calibration made for one contanation of lens settings, slits and pass energy wil not necessarily be vahd for any other setting of the lens, slits and pass energy. Many spectroscopists make accurate measurements under one oØimum set of conditions and then only that set of analyser conditions needs calibration. Any calibration nw.de Is only valid for the combination of settings used.

5.5 Operating the instrument

Operate the instrument in accordance with the manufacturers documented instructions. The instrument shall have fully cooled following any bakeout. Ensure that the operation is within the manufacturer’s recommended ranges for X-ray pow. counting rates, spectrometer sc-an rate and any other parameter specified by the manufacturer. Check that the detector multiplier settings are correctly acusted. For multidetector systems, ensure that any necessary optimizations or checks described by the manutacturer are conducted pnor to this calibration.

5.7 Measurements for the peak binding-energy repeatability standard deviation and the scale linearity

5.7.1 The repealabibly standard deviation of the peak binng energy, . is measured, as described from 5.7.4

10 5.7.7, using the Au 72 Ag 3d or Cu L3VV. and Cu 2p2 peaks and need usually only be done for the first enorgy calibration for a given comblnaton of settings. The value of o .s valid only for the selected set of conditions and involves a significant contribution from the sample-positioning procedure used for the analysis. For consistency, this sample-positioning procedure shall folow a documented profocol which takes account of the manufacturer’s recommendations, This part shall be conducted for each cho.ce of spectrometer operating settings requiring energy calibration as chosen at 5.4. It may also need to be repeated after any substantive modifications to the instrument.

AS ISO 15472 pdf download – Surface chemical analysis—X-rayphotoelectron spectrometers—Calibration of energy scales