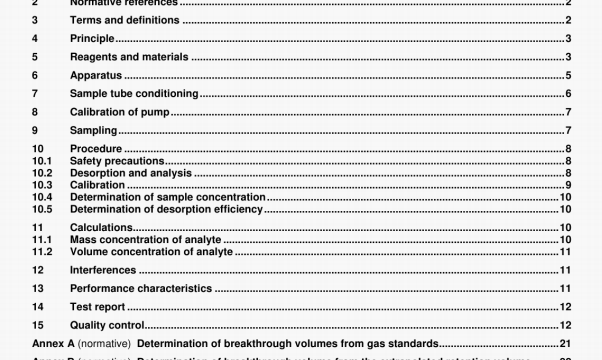

ISO 16017-1 pdf download – lndoor, ambient and workplace air —Sampling and analysis of volatile organiccompounds by sorbent tube/thermal desorption/capillary gas chromatography 一 Part 1: Pumped sampling.

6.4 Syringes, including a precision 10 lii liquid syringe readable to 0,1 p1. a precision 10 p1 gas-tight syringe

readable to 0.1 p1 arid a precIsion 1 ml gas-tight syringe readable to 0.01 ml.

6.5 Sampling pump

The pump should fulfil the requirements of EN 1232 1101 or equivalent.

The sampling pump shall be in accordance with local safety regulations.

6.6 Plastic or rubber tubing. about 90cm long, of app’opnate diameter to ensure a leak-proof fit to both pump and sample tube or tube holder, it used. Clips should be provided to hold the sample tube and connecting tubing.

Sampling tubes shall not be used with plastic or rubber tubing upstream of the sorbent. The use of such tubing may mtroduce contaminants or sorbed sampled VOCs.

6.7 Soap-bubble meter or other suitable device f or calibrating pump. The flow meter shall be traceably calibrated to a primary flow standard.

NOTE The use of an uncalibrated rtegral ftow meter for the caibration of pun tto’rates may result in systematic errors of several tens of percent.

6.8 Gas cliromatograph. filled with a ftame ionization. photoionization detector, mass speclronielric or other suitable detector, capable of detecting an injection of 0,5 rig toluene with a signal-to-noise ratio of at least 5 to 1.

The gas chromatograph shall have a capillary column capable of separating the analytes of interest from other con,ponenls.

6.9 Thermal desorptlon apparatus, for the two-stage thermal desorption of the sorbent tubes and transfer of the desorbed vapours via an Inert gas flow Into a gas chromalograph.

A typical apparatus contains a mechanism for holding the tubes to be desorbed whilst they are heated and purged simultaneously with inert carrier gas. The desorption temperature and time is adjustable, as is the carrier gas flowrate. The apparatus should also incorporate additional features, such as automatic sample tube loading, leak testing, and a cold trap in the transfer line to concentrate the desorbed sample (10.2). The desorbed sample. contained In the purge gas, Is routed to the gas chromatograph and capillary column via a heated transfer line.

6.10 Injection facility for preparing standards by liquid spiking.

A conventional gas cliromatograpliic injection port may be used for preparing sample tube standards. This can be used in situ, or it can be mounted separately. The carrier gas line to the injector should be retained. The back of the infection port should be adapted if necessary to fit the sample tube This can be done conveniently by means of a compression coupling with an 0-ring seal,

7 Sample tube conditioning

Prior to use, tubes should be reconditioned by desorbing them at a temperature at or just above the analytical desorption temperature (see arw’rex E). Typical conditioning time is 10 miii with carrier gas ftowrate of 100 mLmin. The carrier gas flow should be in a direction opposite to that used during sampling. Tubes should then be analysed. using routine analytical parameters, to ensure that the thermal desorption blank is sufficiently small. It the blank is unacceptable. tubes should be reconditioned by repeating this procedure. Once a sample has been analysed, the tube may be reused to collect a further sample immediatety. However, it is advisable to check the thermal desorption blank if the tubes are left for an extended period before reuse, or if sampling for a different analyte is envisaged. Tubes should be sealed with metal screwcaps with combined PTFE ferrule fittings and stored in an airtight container when not used for sampling or being conditioned.

NOTE The sorbeni tube blank level is acceptable it interfering peaks are no greater than 10% of the typical areas of the anatyles of interest.

ISO 16017-1 pdf download – lndoor, ambient and workplace air —Sampling and analysis of volatile organiccompounds by sorbent tube/thermal desorption/capillary gas chromatography 一 Part 1: Pumped sampling